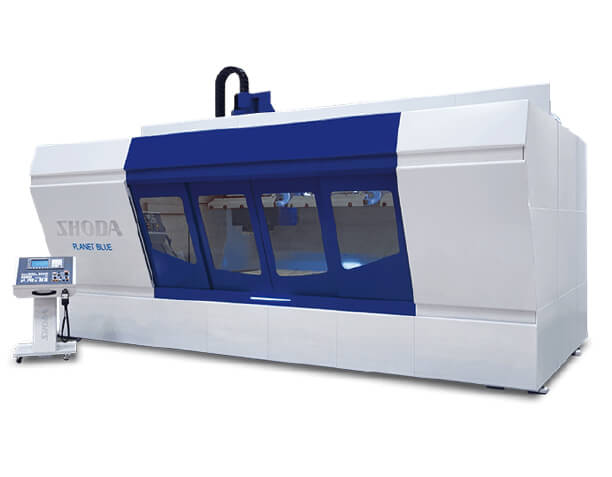

Planet Blue SPB1-3015

Planet Blue SPB1-3015

| PRODUCT CHARACTERISTICS |

|---|

| Completely dust-free structure |

| Dust collecting function with the spindle |

| Flash function |

| Pressure balancing function |

| Rotating brush cleaning function |

| Energy Savings and Powerful spindle |

| Hanger-type ATC |

| Angle head C-axis function (optional) |

| items | specifications | contents |

|---|---|---|

| stroke | X Axis Stroke (Spindle left & right) | 3,000mm |

| Y Axis Stroke (Spindle column back &forward) | 1,500mm | |

| Z Axis Stroke (Spindle Up & Down) | 500mm | |

| Table | Table Size | 3,000×1,500mm |

| Table Surface | Vacuum Table | |

| Spindle Nose to Table Top | 605mm | |

| Spindle | Output | 11/15 (continuously/15min. Constant) |

| Speed | 100~20,000min-1 | |

| Spindle Nose | BT30 MAS-Ⅱ | |

| ATC Unit | Tool Change System | Fix Address Random |

| Tool Type | BT30 MAS-Ⅱ | |

| Tool Storage | 16 | |

| Tool Max. Dia. | φ80 | |

| Tool Max. weight | 3kg | |

| Feed Rates | Rapid Traverse | X:60,000mm/min Y:40,000mm/min Z:15,000mm/min |

| Cutting Feed | XY:1~15,000mm/min Z:1~10,000mm/min | |

| Vacuum | Vacuum | 5.5kw |

| Control | CNC System | SHODA-FANUC Series 0i-M Simultaneous 4 Axis Control |

| Utility | Input Voltage | 34kw |

| Air Pressure | 0.5Mpa | |

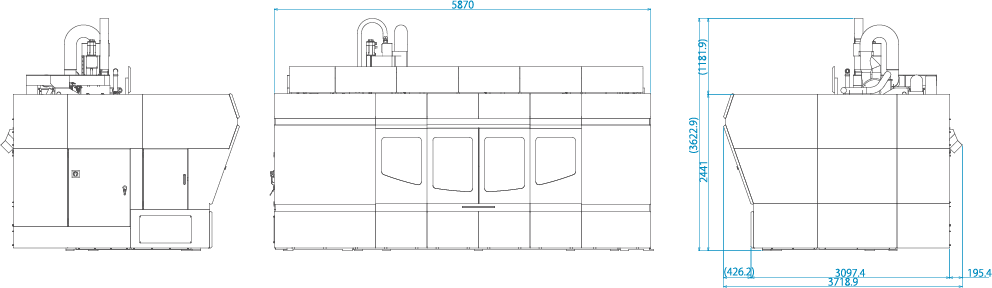

| Size | Floor Space | Width×Length×Height=6,000×3,800×3,700mm |

| Machine Weight | Approx. 5,500kg |

| CNC System | SHODA-FANUC Series 0i-M | |

|---|---|---|

| System Spec. | Control Axes | 4 Axes (Plus C axis : 5 axes) |

| Simultaneously Controlled axes | 4 Axes | |

| Axis name | X, Y, Z, V ※OP : C | |

| Increment system | 0.001mm 0.001deg | |

| Increment traverse rate | 0.001mm 0.001deg | |

| External Interface Function | Reader/puncher interface | |

| Memory Card Interface | CF card Correspondence | |

| Display | 8.4 color TFT LCD | |

| others | ||

| CNC Functions | Rapid Positioning | Backlash compensation |

| Helical interpolation | Exact stop | |

| Sub program call (10 folds nested) | Automatic reference point return | |

| Automatic acceleration/ deceleration | Workpiece coordinate system 48-pairs | |

| Number of registerable program (400) | plane selection | |

| Tool position offset | Jog override | |

| Mirror Image | Machine lock | |

| Pitch error compensation | Tool length offset | |

| Exact stop mode | Dwell | |

| Absolute/ incremental | Option block skip | |

| Coordinate system setting | Alarm history display | |

| Circular interpolation by R Programming | Cutting Feed Override | |

| Rabid Feed Override | Auxiliary function lock | |

| Dry run | Part program storage size (512KB) | |

| Tool diameter offset | Custom macro | |

| ※Specifications are subject to change without prior notice | ||

| Category |

|---|

| PLANET BLUE |

| Applications and materials |

|---|

| Aircraft parts |

| CFRP parts |

| Auto parts |

| Building materials |